Vacuum hardening and carbonizing

Vacuum hardening

Vacuum hardening is a heat treatment process to achieve high hardness/strength on steel.

It consists of austenitsing, quenching and tempering on order to reach the required hardness.

The advantage of vacuum hardening: no surface oxidation, less de-carburation and less dimensional charges.

Typical materials: 1.2379, 12343, 14112, HSS etc.

Vacuum carbonizing

LPC is a case hardening precess produced in a vacuum furnace using acetylene gas at very low pressure. The LPC process is to obtain a hardened surface layer of tempered martensite and a tough core. At temperatures of about 900-950 degrees a hardened surface layer is formed.

After the carburizing step te products are cooled down with 6-12 bar nitrogen.

Advantages of LPC: surface not oxidized, low disortion, penetration of carbon in deep holes, precise control of case depth.

Some applications are: gears, shafts, nozzles.

Typical LPC materials: 1.6578, 17131, 1.7147, 1.5918.

Possibilities at dominial for vacuum hardening?

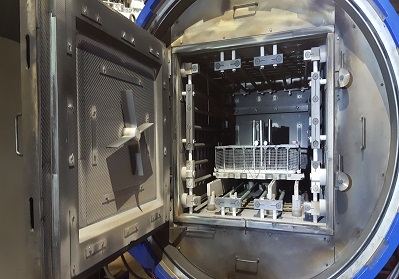

- Dominial has the latest vacuum furnace technology with a max. of 12 bar cooling rate.

- Due to this high cooling rate, Dominial can also treat oil-hardening steel grades in the vacuum furnaces.

- Monitors this treatment 24 hours a day to ensure quality.

- Dominial has 4 vacuum furnaces with a maximum dimension: 700x900x1200.

- Maximum weight: 2000KG.

Possibilities at Dominial for vacuum carburizing?

- Dominial has the latest vacuum carburizing technique.

- Carburizing depth up to 3mm can be easily reached.

- Monitors this treatment 24 hours a day to ensure quality.

- Dominial has 4 vacuum furnaces.

- Maximum dimension for LPC furnace is: 600x600x900.

- Maximum weight: 800KG.

Contact Form Vacuum Hardening and Carbonizing

Would you like more information about Vacuum Hardening and Carbonizing? Please contact us!